For major logistics and material handling operations, efficiency is everything. When a business operates a distribution network on an international scale, every second counts. Every workflow has to be optimized. Every change has to be carefully implemented, or the results can be catastrophic. In these operations, a functional enterprise resource planning (ERP) solution isn’t just […]

One Need, One App. Expand As You Grow.

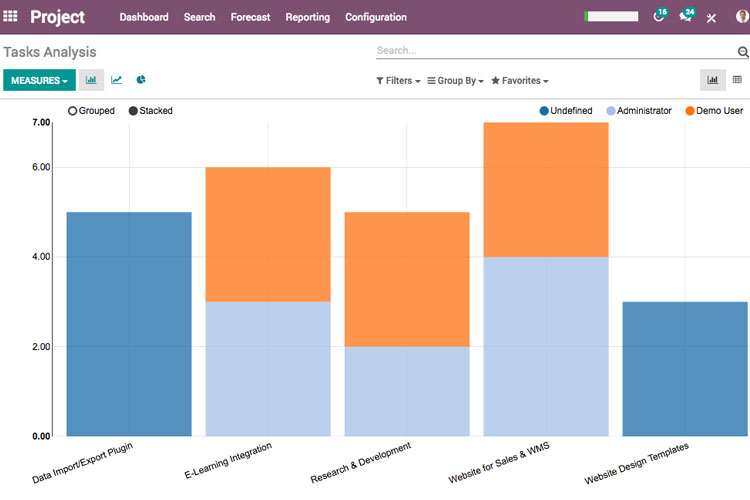

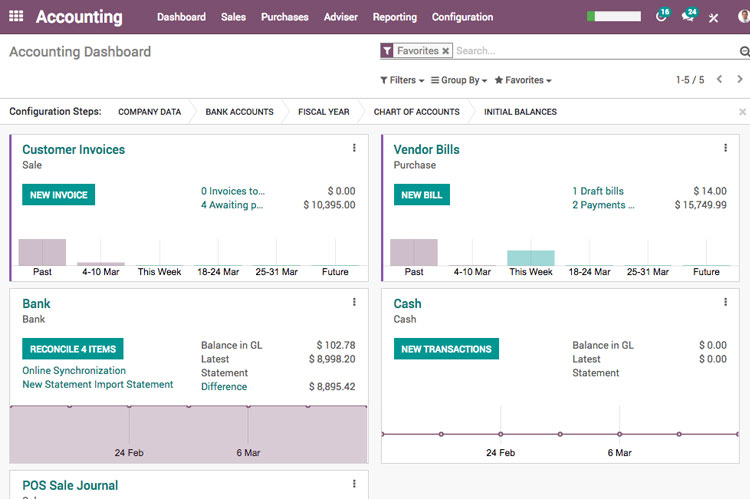

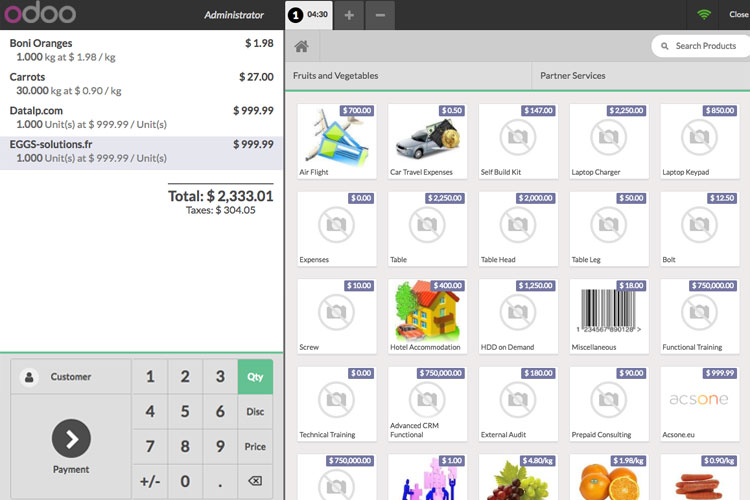

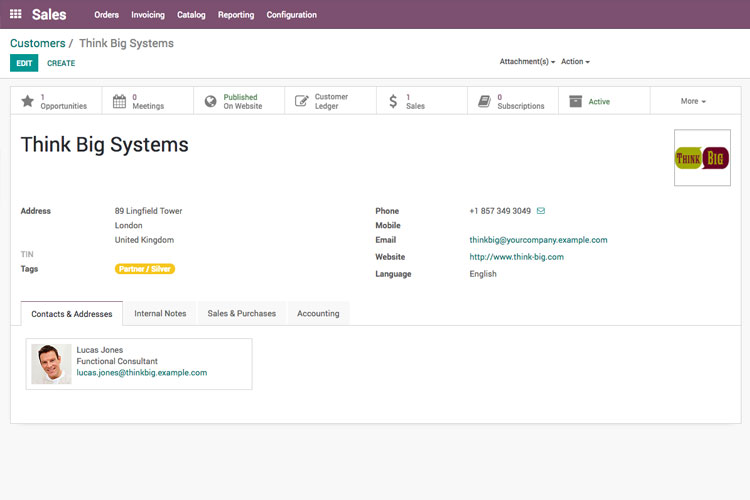

Odoo’s suite of comprehensive business applications includes modules such as Customer Resource Management, Sales Management, and Point of Sale. Blue Stingray can help your business take advantage of the ERP's powerful features and adapt them to your organization's unique workflow. Whether you're switching from another ERP or starting fresh, we're ready to help.Consultation

Certified Partner

We focus on enhancing your productivity and simplifying your workflow.

Our approach ensures an efficient, fully customized Odoo implementation that can revolutionize the way you do business.

Personal

As a certified Odoo partner, we can personally meet with you to analyze your business needs and offer a comprehensive solution for overhauling tedious and time-consuming tasks.

Advice

Get advice on how to organize your deployment, which metrics to watch, and how to build a successful ERP strategy.

Direction

Understand key Odoo features, plan vendor paths, and more.

Training

Blue Stingray is available for online and onsite training sessions to assist with the functional and technical understanding of Odoo.

Support

Odoo Support Team

Deployment & Support

Our team of experienced St. Louis Odoo developers and engineers are ready to implement a wide range of Odoo modules, Odoo apps, and Odoo add-ons.

Deployment

By utilizing rapid, agile development and coordinating with our clients, we're able to offer solutions for clients of all sizes.

Support

Once you’re up and running, we will continue to provide personalized support to keep your business operating smoothly and efficiently. Blue Stingray provides comprehensive Odoo ERP support & maintenance packages.

Implementation

Implementation Team

The ERP implementation process encompasses several different phases.

Blue Stingray can help you with evaluation, planning, configuration, data migration, deployment, and user training.

Implementation Methodology

Implementation encompasses the whole process of integrating and deploying an ERP, including evaluating options, establishing specifications, planning the deployment, configuring the software, loading data, installing the product, and training the users. It does not generally extend to software customization, nor support and maintenance.

Maintenance

Maintenance Team

Success Packages

Blue Stingray provides ERP support packages. This is the best option for clients who are in need of frequent support and customizations.

Support

Support and maintenance are the key factors for the smooth functioning of ERP solutions. Expert Odoo support and maintenance provided by Blue Stingray have efficient and affordable results.

Maintenance

After implementation of Odoo ERP, your company will need Odoo to work seamlessly. If you require updates or process improvements, you'll need changes to Odoo ERP. Blue Stingray can help you keep Odoo running seamlessly.

Odoo Self Hosted Setup

(Enterprise or Community)

This support package is for companies that want to try Odoo, but are not ready to commit to full implementation yet. The client will be responsible for project management and will be learning the system on their own. Blue Stingray will help with the initial Odoo installation and setup as well as with the monthly server maintenance.

$4,000 One Time

+

$220 Monthly Cost$120 Monthly Server Cost

$100 Monthly Server Management Cost

$100 Monthly Server Management Cost

Included:

- 4 Core CPU

- 8 GB RAM

- 500 GB Storage

- 12,000 Emails Per Month

- Linux Based Operating System

- Custom DNS Configuration

- SSL Configuration

- Decide on Community or Enterprise Source Code

Odoo Getting Started Training Package

(Enterprise or Community)

This support package is for companies that have already started Odoo implementation or have signed up for Blue Stingray’s Self Hosted Setup package and need training, support, consultation, or general guidance. We will help you gain a full understanding of Odoo, including best practices for using the system.

$5,000 One Time

Included:

- 50 Hours of Best Practices Training, Support, and Consulting

- Training

- General Odoo Support

- Guidance With Odoo

- Teach Best Odoo Practices Methods

- Access to an Odoo Expert

- Odoo Consulting

Odoo Self Hosted Maintenance Package

(Enterprise or Community)

This support package is for companies that have already started Odoo implementation or have signed up for Blue Stingray’s Self Hosted Setup package and want to keep their system maintained going forward.

$600 Monthly

or

$6,500 Annually ($700 Discount)Included:

- Manage Daily Automated Backups

- Monthly Server Maintenance

- Monthly Odoo Updates, Software Patches, and Security Updates

- Server Costs Apply Separately

Odoo Continued Success Package

(Enterprise or Community)

This package is for companies that already have Odoo implemented and need general system support. The package includes a block of monthly hours that will be used on as-needed-basis for answering questions, quick training sessions, or small configuration changes.

$2,000 Monthly

or

$20,000 Annually ($4,000 Discount)Included:

- 20 Hours Per Month Training, Support, Configuration Updates, and Consulting

- Training

- General Odoo Support

- Guidance With Odoo

- Teach Best Odoo Practice Methods

- Access to an Odoo Expert

- Odoo Consulting

- Odoo Updates

- Odoo Configuration and Tuning

Odoo Simple Implementation Package

(Enterprise or Community)

This support package is for companies that have already started Odoo implementation or have signed up for Blue Stingray’s Self Hosted service agreement and need some more help getting the system setup. This package offers a solid block of hours to use for requirements gathering, training, support, system configuration, and data migrations.

$20,000 Paid Over 3 Months

Included:

- Everything From “Getting Started Training Package”

- 28 Hours of Requirements Gathering and Business Analysis

- 60 Hours of System Review and Core Configurations

- Company Wide Configurations

- Module Specific Configurations

- Security and Permissions

- Data Reviews

- 80 Hours of Data Migrations

- Dedicated Odoo Team

Odoo Champion Implementation Package

(Enterprise or Community)

This support package is for companies that are doing large, out of the box Odoo implementations. It is recommended for companies that are pulling a lot of systems together, or need quite a bit of support due to the size of their project.

$45,000 Paid Over 6 Months

Included:

- 50 Hours of Requirements Gathering

- Everything From The “Getting Started Training Package“

- 50 Additional Support and Consulting Hours

- 250 Hours of Implementation, Configurations, and Minor Customizations

- Company Wide Configurations

- Module Specific Configurations

- Security and Permissions

- Data Reviews

- Report Customizations

- Minor Customizations To Out of The Box Functionality

- 100 Hours of Data Migrations

- Dedicated Odoo Team

- [Community] Unlimited Number of Users

- [Community] All Odoo Community Modules

- [Enterprise] Enterprise Level Features

- [Enterprise] Requires Enterprise User Licenses

ERP Clients Served: